It was a pleasure to visit Zanini’s R&D office and plant in Barcelona. Finally, I got to see where their magic happens, after they joined DVN two years ago. I’ve known of their work since 2003; one of my first developments with Hervé Sanchez from Renault — and not the easiest one — was to develop a support for the licence plate for the Mégane cabriolet in Japan, and only Zanini had interest in developing it. For all lighting engineers involved in implementation of licence plate lamps with all possible configurations (Mexico, Egypt, Japan, etc…), I think you can image the issue. Thanks to that I kept in good contact with them during my whole career.

Zanini are a family-owned company created 55 years ago in Barcelona, now with more than 1,800 employees in 10 different countries, including 13 factories in Europe, China, Mexico, the USA, India, and more. They are well known for wheel trim, with 100 million wheel deco parts produced per year for over 60 brands. Zanini developed their own primerless painting process, as well as Zanichrome, their new technology which allows electromagnetic transparency and backlighting. It’s done with PVD sputtering to produce metallic finishes.

August Mayer, Head of Advanced R&D and Innovation, joined Zanini in 1999. He brought a lot of knowledge in radar, and got the idea to develop radar-transparent, metal-looking components to be placed in front of radar sensors.

Zanini started their first radome project (radar behind a chrome logo) with a Cadillac prototype in 2009, and then the first Zanini radome to enter mass production was on the SEAT Ateca in 2016. Then came heated radomes (Mercedes 2019), lit logo radomes (VW 2021– world’s first), invisibly-heated radomes (BMW 2021), radomes without any air gap (Renault 2023), smart radomes (Volvo ex90 2024) including a sensor to detect overheating, and first lit, heated radome on the Mercedes CLA in 2025.

Zanini have developed complete skills for this kind of development, including electromagnetic full-wave simulations and thermal and optical simulations.

Radome technology is really interesting, integrating multiple technologies including injected components, films, hot stamping, painting, metallization, and full radar transparency control at the end of the assembly line.

Classical aluminium metallization cannot be used for radar. Mercedes developed a special metallization technology with indium, and Zanini later developed their own with silicium and germanium for radar transparency.

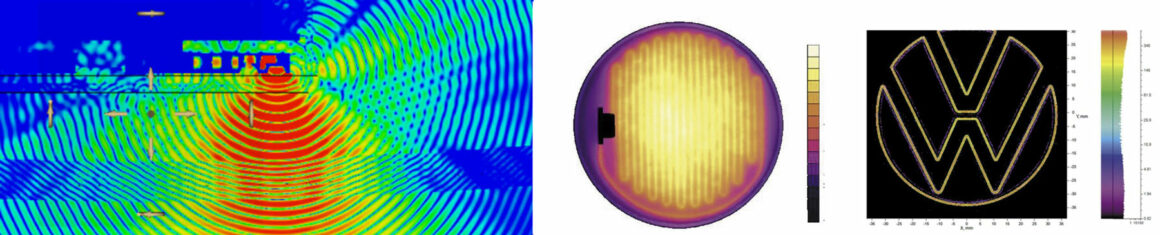

To increase efficiency of the radar, one must minimize any air gap between the radar and the A-surface of the vehicle body. How can you also include light and heating in this case? We took time to analyze in detail the VW lit radome they have in production at the Barcelona plant.

First, the outer lens. It’s done in 2K crystal black, on which Zanini apply a UV hardcoat to protect from the sun and scratches on the A-surface, and metallization as well as laser etching on the B-surface. Thanks to metallization removal, light will go through the lens.

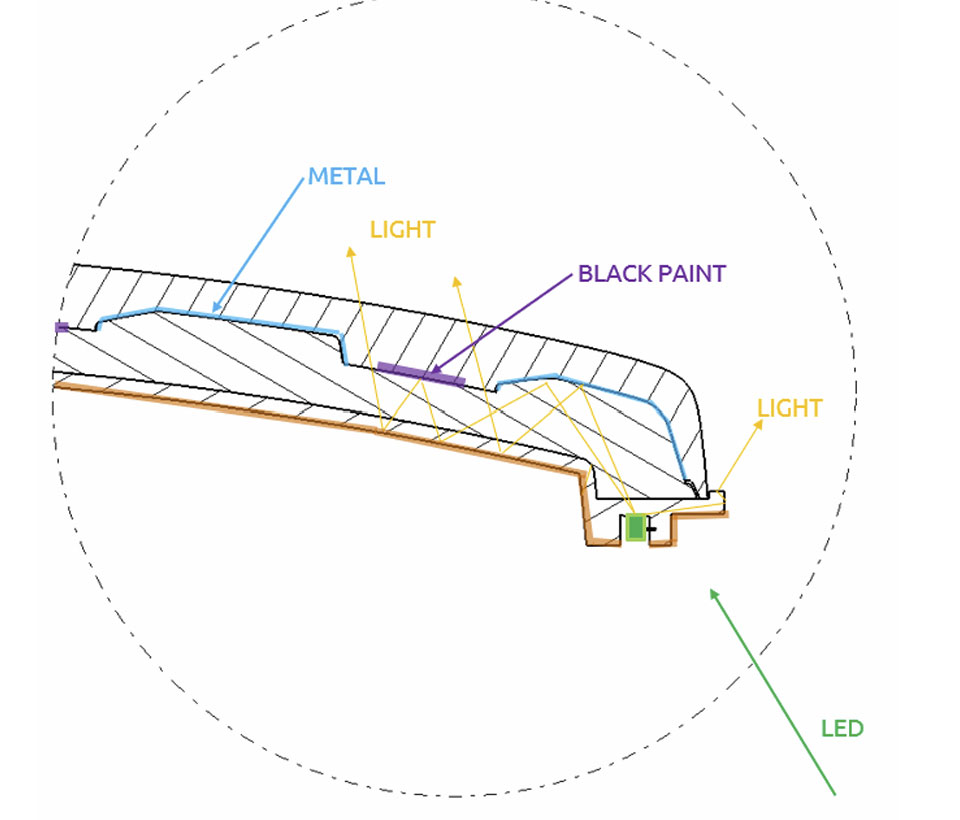

The housing is in ABS-PC, on which is assembled the PCB including LEDs. In between there’s the light guide. an injection of transparent PC with white paint hot-stamped on. Light from the LED, all around the round shape, is refracted using total internal reflection on both light guide surfaces, and reflects on the white paint of the light guide to be outcoupled.

These four components are assembled and affixed together by laser welding on the lens/housing contour, and in some central areas to control the two air gap layers (between light guide and housing, and between the front lens and light guide). This is key to keep a good radar transparency.

During final assembly, light homogeneity is fully checked with a luminance camera, and radar transparency is likewise checked.

Efficiency is quite good: 8-cd light intensity, luminance about 5,000 cd/m2, and power consumption of 7.7W.

On the Mercedes CLA, there is an additional complexity: the need of a heated and lit radome. Heated film is used as the A-surface. It’s overmoulded on the 2K black crystal outer lens, and a UV hardcoat is added.

Zanini are making, for the Mercedes CLA, their first lit and heated radome. Two versions exist, to meet different requirements: there’s no size limitation in the USA or China, so the complete star + ring is lit, while to comply with the ECE lit-logo size limitation of 100 cm2, only the star illuminates.

As Zanini are leaders in wheel trim and experts in lit logos, discussion came up about a lit logo in wheel trim. I wrote an article about this topic last March, and it was interesting to exchange thoughts. For sure they are working on it.

Zanini’s idea is to work on a lit floating emblem.

One challenge is the need of power to light the emblem on the rotating wheel. Zanini are working on a self-sustaining power system: the emblem generates its own energy through the rotation of the wheel, eliminating the need for external wiring or batteries. The system activates the lighting feature once the vehicle reaches a speed of 20 km/h, ensuring visibility and aesthetic appeal even while in motion. The illumination remains stable and consistent up to speeds of approximately 125 km/h, maintaining the emblem’s horizontal position and enhancing its visual impact without compromising performance or safety.