Site Visit: Stellantis CRF Lab

Torino is the historic automotive capital of Italy, the city of automotive design, and the location of Stellantis CRF Global Materials Lab which DVN-I Workshop attendees visited on the first morning. This visit set the tone of the workshop, with a look at the material lab, the soft trim lab, and the Color & Materials Lab, where participants got a practical understanding of new natural materials, recycled materials, biomaterials, going through thousands of tests for wear, elongation, fatigue, climate, humidity, snagging, aging, sunlight exposure, and many more.

The group had the opportunity to visit La Pista 500, Pinacoteca Agnelli, the track historically used by the Fiat factory for testing cars on the roof of the Lingotto—now it has a rooftop garden which has become a spectacular panoramic walkway through art, complete with a museum.

CRF (Centro Ricerche Fiat, the Fiat Research Center), headquartered in Orbassano (Turin) with other branch sites in Italy, was established in 1978. As a focal point for research activities of Stellantis, CRF’s mission is to develop and transfer innovative vehicle powertrains, systems, features, materials, processes, and methodologies to improve Stellantis products; represent Stellantis in European collaborative research programs, and support Stellantis’ intellectual property-related activities.

CRF develops research and innovation along three principal axes of sustainability:

- Environmental sustainability, which encompasses all aspects relating to energy efficiency as well as to the reduction of the impact on the environment over the entire lifecycle of the vehicle;

- Social Sustainability, focusing on the safety of transportation systems through the development of active, passive, preventive and cooperative solutions while addressing the mobility of all users irrespective of their specific needs, and

- Economically sustainable competitiveness, oriented towards viable innovation, i.e., improving the performance and functionality of new vehicles in a cost-effective manner while reducing the time-to-market of research results.

Keynotes

Stellantis CMF Innovation, the Global Creative Sustainable Perspective

Danila Giordano, Stellantis CMF

Danila Giordano presented the role of CMF in design, the development of product experience, the content storytelling, and the construction of brand identity with design, surfaces and materials.

CMF focuses on sustainability and innovation, developing next generations of materials in collaboration with suppliers and with other industries. The main innovation directions are circular design, biomaterials, and advanced technology (lightweight material, ‘AI’ aesthetics, augmented materials…).

The challenge here is to serve 14 brands, with a global perspective comprising different viewpoints.

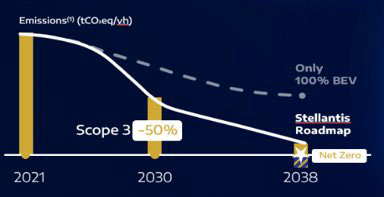

Stellantis’ commitment to zero net carbon (ZNC) includes circular design, design for longevity, and design for monomaterial.

Stellantis Material and Sustainability Strategy

Vito Lambertini, Stellantis CRF Innovation Manager

Vito Lambertini presented Stellantis’ material and sustainability strategy, and the main projects launched to support this strategy.

Stellantis has committed to achieving, by 2030, 40 per cent green materials in complete vehicles, 35 per cent of plastics, and half of metals. « Green » here means recycled, NF, and renewables. Furthermore, all vehicles must be designed to be 95 per cent recoverable (by weight), and 85 per cent recyclable—that’s what’s required by the european end-of-life vehicle directive.

A newer objective is 25 per cent of plastics to be recycled in 2031, which means an increased number of parts to be dismantled. Example on actual car: 98 kg of PCR (postconsumer-recycled) plastics, of which 25 from end-of-life vehicles..

Presently, the state of the art looks like this:

- Mechanically recycled TP: All models in Europe and North + South America > 25 kg per vehicle

- Recycled PET for textile and carpet, > 80 per cent recycled content

- Recycled Tetrapaks in the new Fiat Grande Panda door panel, > 20 kg per vehicle: about 1 kg of Tetrapak per car.

Biomaterials are also a key strategic direction. For example:

- Jeep Renegade > 4 kg per vehicle; about 2 kg of wood fibers per car

- Bio-based polymers for seat pads

- Peugeot 308 > 5 kg per vehicle: 1 kg of hemp per car

To support a net-zero-carbon goal, Stellantis is working to identify breakthrough materials and components to halve CO2 emissions and promote the circular economy with no TPC impact.

New potential projects include interior trim with NF and visible NF, High PCR projects, ‘smart’ surfaces, biopolymers, green textiles with bio-based fibers, recycled fibers, and ersatz leathers.

Stellantis is also working to develop new TP compounds with high recycled content from PCR feedstocks with the expected output to quickly have materials available with robust value chains.

Italdesign (Giovanni Pizzi, Head of Interior Design; Luca Bonassi, CMF Designer)

Italdesign is a state-of-the-art customer-centric, method- and fact-based company operating in styling, engineering, production, and new mobility solutions.

Headquartered for 55 years in Moncalieri, Turin, with over 1,200 employees working in Italy and abroad, Italdesign has been collaborating with major and emerging national and international players in the mobility, product and transportation design world.

Two years ago Italdesign decided to rebuild its image with the concept of ‘Ideeners’, the merging of engineering and ideas. In Italdesign’s presentation, their most recent prototype car—the Quintessenza—was shown.

The design philosophy is rooted in a human-centric approach. The project revolved around reconnecting humans with nature, steering towards a concept of ‘digital detox’, aiming to emphasize freedom through travel. A hybrid architecture that blends the pleasure of driving with the opportunity to become an integral part of the surrounding environment, ultimately allowing one to immerse themselves in the landscape like a telescopic architecture and observe the landscape where technology exist but is completely Integrated.

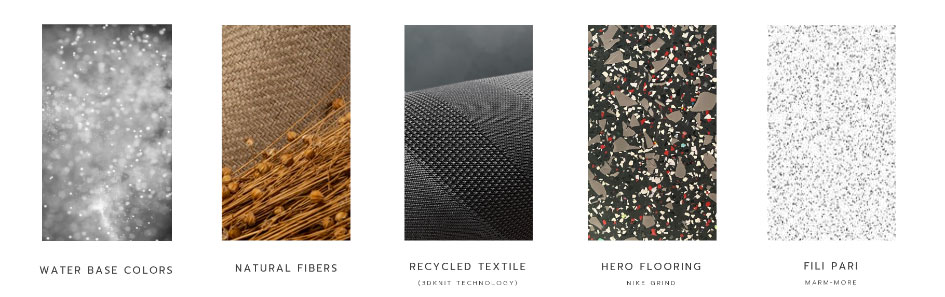

The key words about the Quintessenza are flexibility, sustainability and integration. The interior has been designed with a choice of color and materials which create an environment for healing and transformation, where technology exists but holds a value completely integrated into the material.

Features include:

- Water-based colours to lower environmental impact and reduce emissions

- Natural fibers for CO2 and weight reduction

- Recycled textiles for maximum waste reduction, reduction of cost and processing time

- Hero Flooring from recycled shoes and waste, improving durability

- Marble powder microfilm to improve resistance and recycling properties

The world premiere of the car was at Auto China 2024 in Beijing , but the prototype will be visible in the coming months at locations around the world, and in Italy during the next Design Week in Milan, in April 2025.

Ford

On the Road to Better

Norbert Klar, Body Interior Core Engineering; Samantha Scott, Color Material Designer

Ford’s keynote described the company’s approach to sustainability. They introduced their latest EVs, the Explorer and Capri, produced in the new electric vehicle production facility in Cologne. The new factory, called the CEVC (Cologne EV Center) was built on the site of the old Ford factory built in 1930, and it is a key element of Ford’s ‘Road to Better’ plan targeting carbon neutrality across their European production facilities, logistics, and direct suppliers by 2035.

Initiatives at this plant include reducing emissions, water use, and energy consumption of the plant. All electricity and natural gas to operate the plant is ‘certified renewable’ electricity and biomethane. Through process changes in the paint shop at the CEVC Ford expects to save more than 1000 tons of CO2 annually compared to the previous process.

In 2016, Ford in Europe also achieved zero waste to landfill across all plants.

The Explorer and Capri interiors include 25 per cent recycled materials, rising to 35 per cent in the trunk and lower hard trim area.

The nonvisible hard trim is made of 100 per cent recycled materials, with saving around 190 tons of CO2 per year.

Norbert Klar showed a comparison of mechanical, chemical recycling and use of biopolymers, with an additional cost respectively raising from 0 to + €0.8. Chemical recycling is more expensive and only makes sense if deployed at large scale, and with extensive usage of clean energy, due to the high energy consumption required for it.

The choice between different sustainable alternatives mainly depends on a decision matrix showing pros and cons of each solution.

Long term goal is of course the establishment of a circular economy, which should not compete with the packaging industry and shouldn’t interfere with well-established circular processes: there is the need to create an automotive industry related to the circular economy.

From the CMF side, Samantha Scott stressed the importance of moving to monomaterials and to complexity reduction, with reduced number of series per model, like Ford did: moving from the 8 series of Focus to the 2 series of Explorer.

Scott also highlighted the fact that cooperation between engineers and designers has brought a better understanding of what can be done on sustainable interior design, by merging creativity and technical expertise.

Session 1: Materials

Borealis

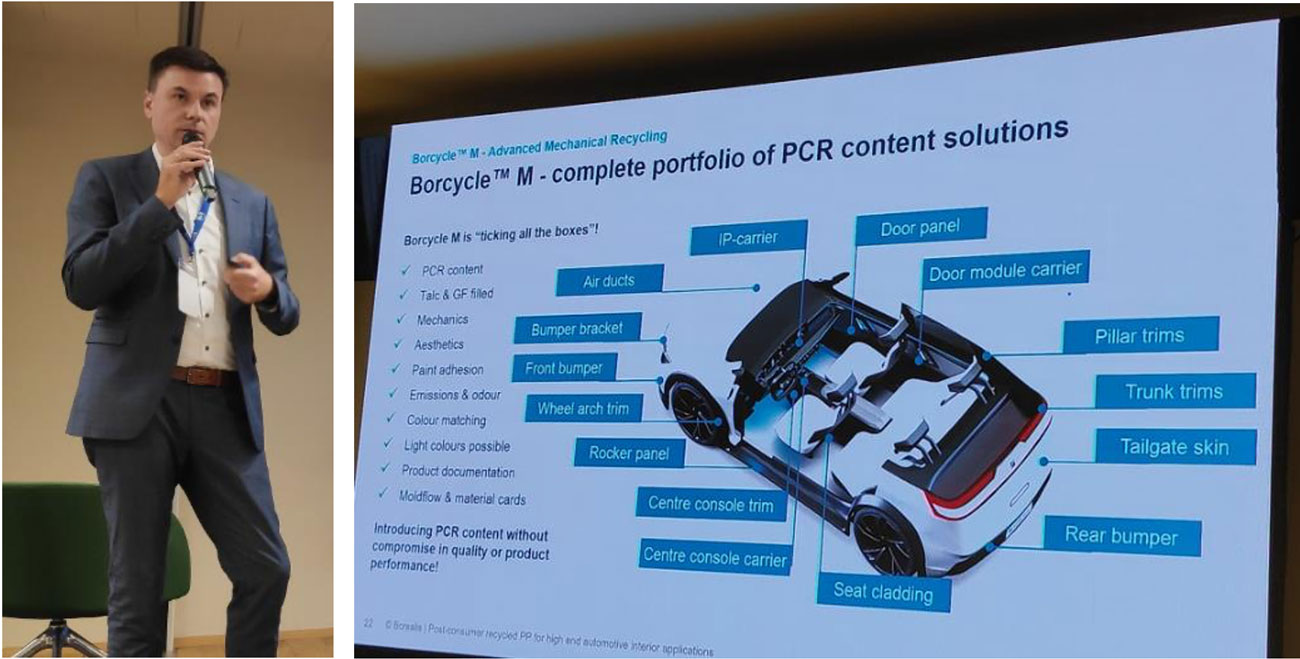

Georg Grestenberger, Borealis’ Senior Application Marketing Manager, spoke on circularity challenges from the new EU end-of-life vehicles regulation, with emphasis on postconsumer recycled polypropylene for high-end automotive applications.

- Borcycle M: this advanced mechanical recycling is an end-to-end technology for a complete portfolio of high performance PCR content solutions, without compromise in quality or product performance.

- Borcycle GD3600SY is a PCR content material for structural interior applications with improved sustainability, robust performance, and compliance with OEM requirements regarding emissions, fogging, and odor.

- Borcycle EE1300SY is a PCR content material for aesthetic interior claddings and trims. It has also an improved sustainability, a high aesthetic quality for class A surface appearance, and also meets the OEM requirements for emissions, fogging, and odor.

According to the new EU end-of-life vehicles regulation: new vehicles shall contain a minimum of 25 per cent by weight of plastic recycled from post-consumer plastic waste, of which 25 per cent originating from recycled ELVs (end-of-life vehicles).

Covestro

Driving the Transition Toward a Sustainable Interior Design

Patrizia Pia Pernice, Head of Covestro Color & Design Center (CMF)

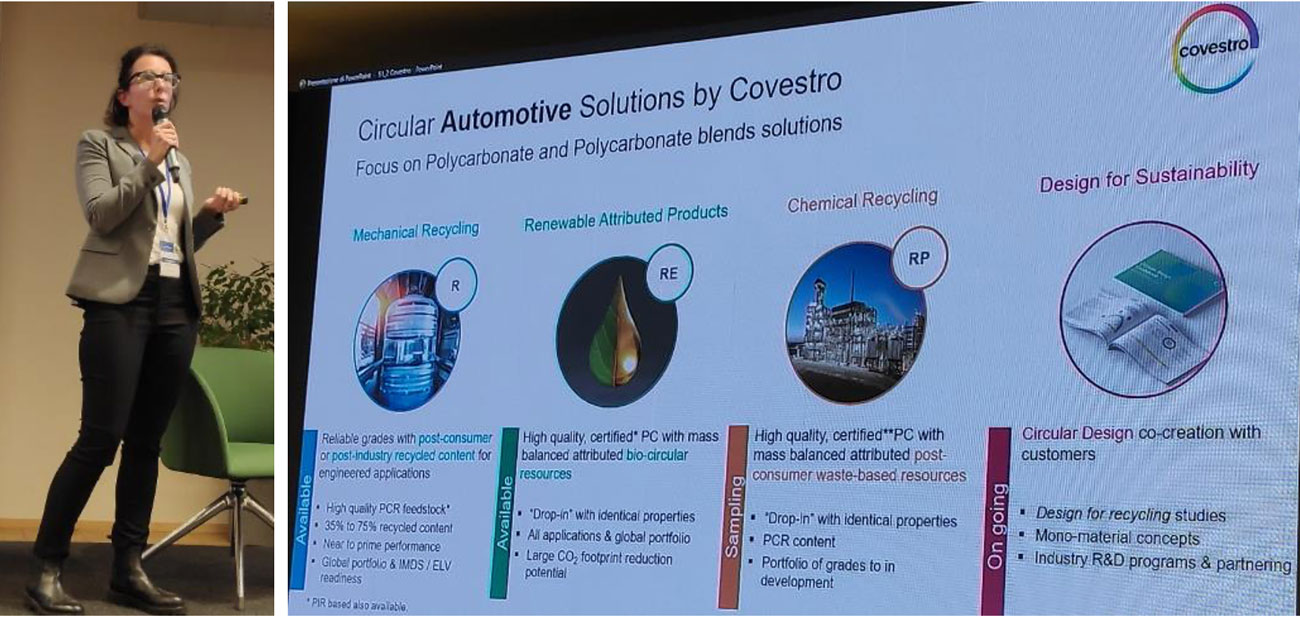

Circular automotive solutions by Covestro have a focus on Polycarbonate (PC) and PC blends for technical, black, and lower-complexity parts.

The transformation of the value chain to enable the production and use of secondary materials needs mechanical and chemical recycling for an attractive carbon footprint reduction and key challenges like costs and energy efficiency.

Mechanical recycling of PC PCR comprises in colorability, tailor made color recipe, and near-to-prime mechanical and rheological properties. Chemical recycling offers many design possibilities with high transparency and colorability, and high optical performance.

Covestro’s four principles for a sustainable CMF design are: timeless design, carbon footprint reduction, in-mold color texture, and defects-into-effects.

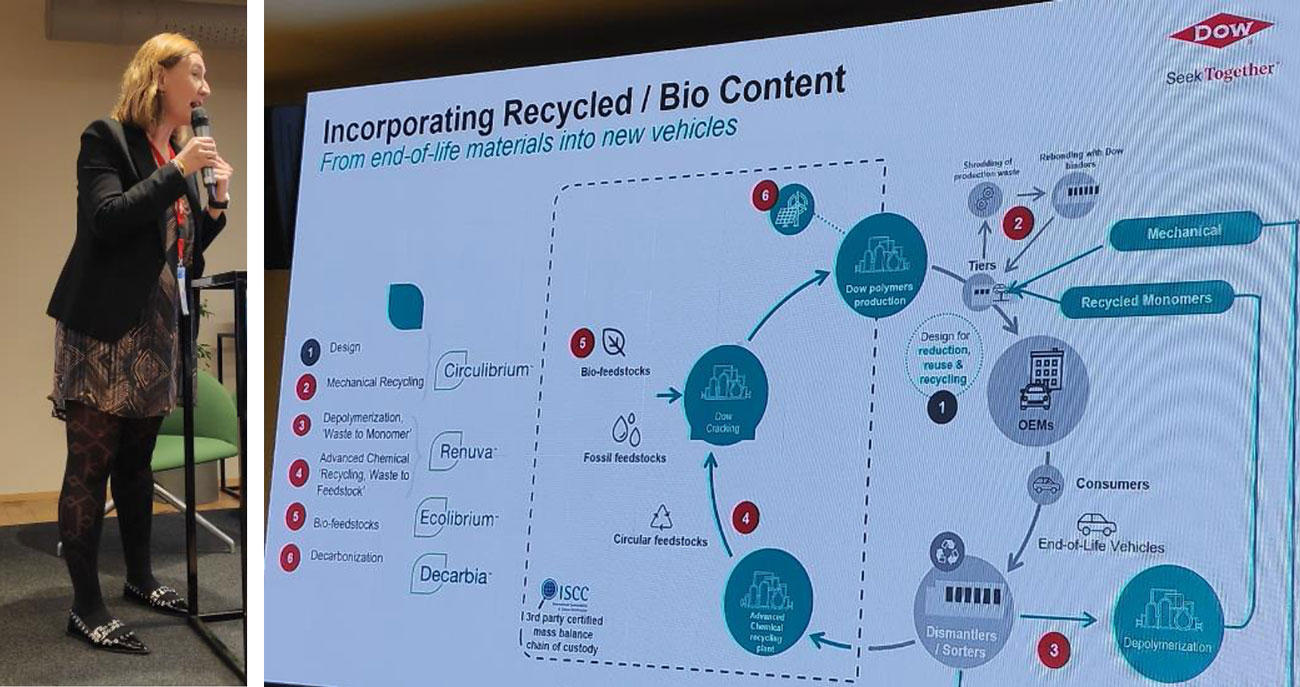

Dow

Design for Circularity Enabled by Material Science

Esther Quintanilla, Dow Global Mobility Marketing Manager

- Specflex CIR: Advanced chemical recycling into automotive parts. It uses recycled waste from the automotive industry to produce circular PU-based (polyurethane) products matching the performance of existing parts. PU is used for skins, headliner, trims, instrument panels, and acoustics / NVH.

- Engage CIR: Bio & chemical recycling—waste to feedstock. Polyoefin elastomers (POE) use other industries’ bioresidues as raw materials to save fossil resources. POEs are impact modifiers for Polyproylene (TPO/PP-EPDM), used for bumpers, frames, door panels, and trims.

- Renuva FF60 is a chemical recycling program: Polyols for slab stock and molded applications, e.g. substitution of conventional foam for seats and mattresses. • Renuva Mobility: Closed loop chemical recycling program: Recycled PU foam from ELVs and turning it into polyols for a significant reduction in the environmental footprint.

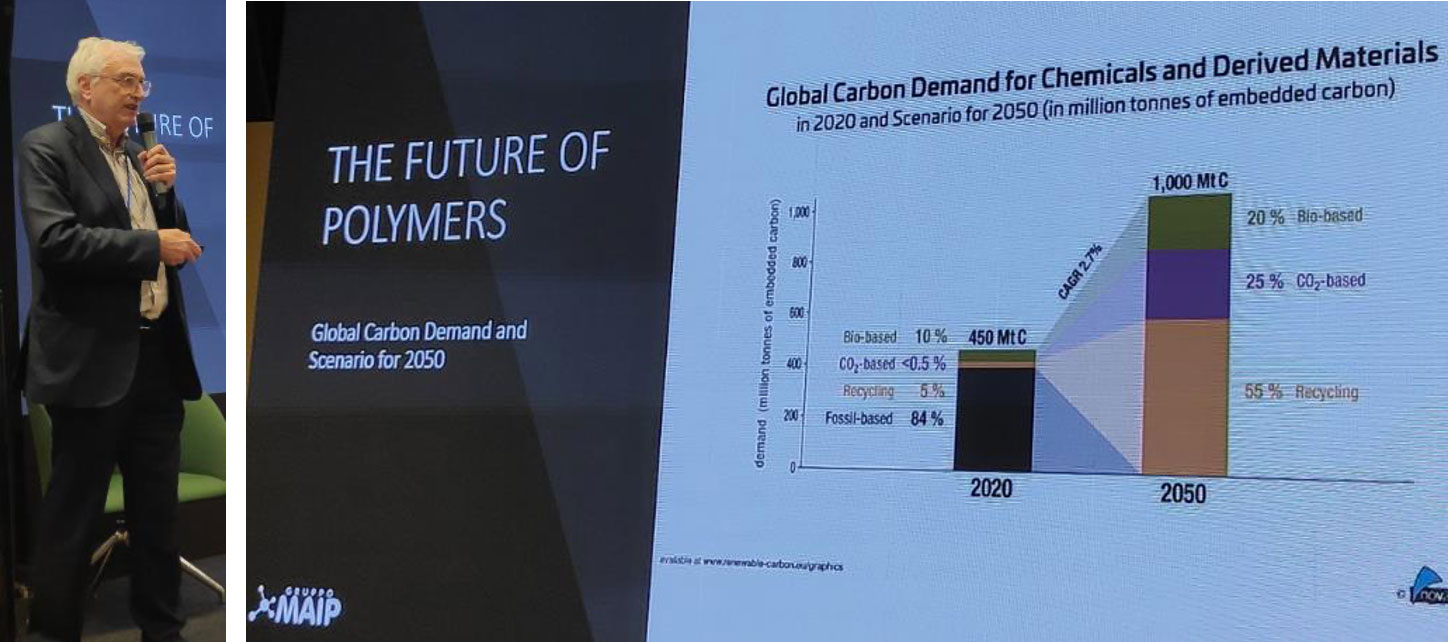

Maip Group

Next-Generation Sustainable Polymers: Revolutionizing the Automotive Industry with Mechanical, Chemical and Molecular Recycling Materials and Advanced Biopolymers

Eligio Martini, Maip President and CEO

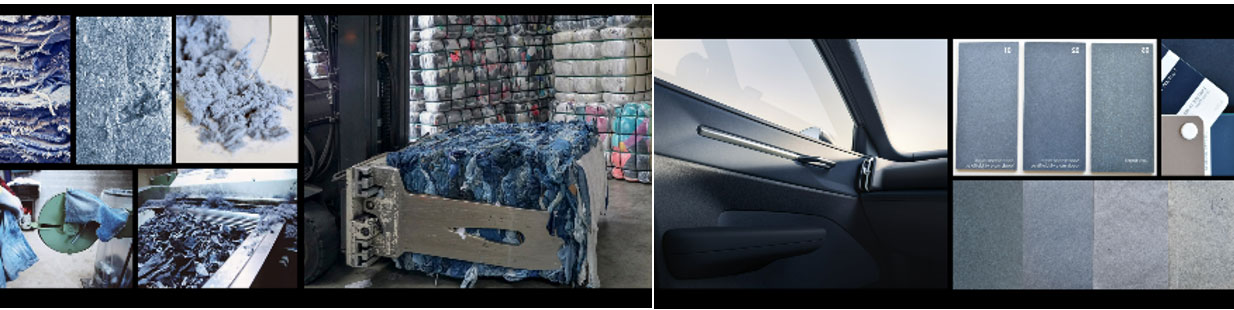

Maip develops several grades of TPU and TPE with recycled textiles (jeans), and they use various green polymers for the production of car components.

Green polymers from natural waste are advanced hybrid materials that come from the addition and ‘combatibilization’ of vegetal fibers into thermoplastic resins. The types of fibers are linen, hemp, jute, straw, wood, rice cortex, wheat, barley, oats, rye, cane, kenaf, ramie, oil palm, sisal, and other suchlike.

Eastman’s molecular recycling technologies have a better carbon footprint compared to processes using fossil-based resources. On this basis Maip can compound and color different materials.

Cheribo C is based on carbon renewal technology (CRT) and Cheribo T and TX on polyester renewal technology (PRT). With these technologies plastic waste becomes the origin of the materials.

Maip Compounding develops a range of innovative compounds based on UBQ flakes and various polymers for thermoplastic polymers.

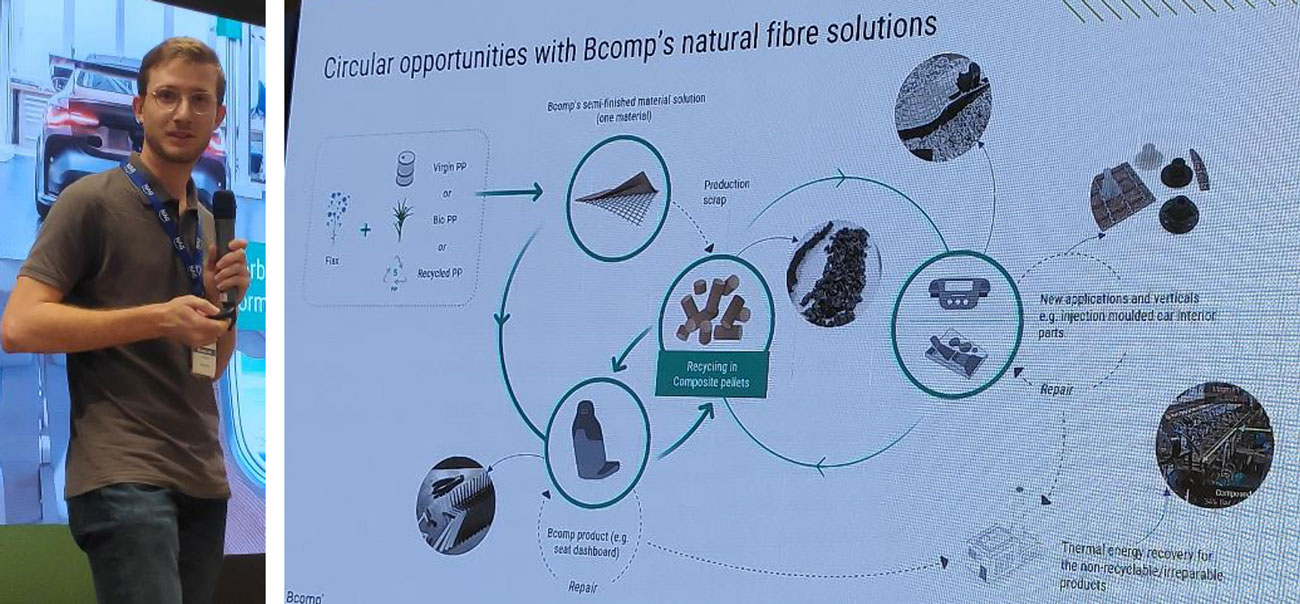

Bcomp

Setting New Standards for Automotive Interiors with Sustainable and High-Performance Natural Fibre Solutions

Nicolas Samson, Bcomp Automotive Project Engineer

Bcomp is a Swiss company providing natural fiber reinforcements in high-performance applications. Their Amplitex technical fabrics offer a versatile array of options.

Bcomp offers lightweight, high performance sustainable material solutions made from flax to reinforcement fabrics and natural fiber parts. The final parts have equivalent stiffness, half the weight, and 60 per cent less carbon emissions than PP or ABS/PC, and carbon savings and unique design opportunities as well.

Amplitex technical fabrics combined with 50 per cent PP is Bcomp’s natural aesthetic solution for surface covers in automotive interior parts. They are also available with a sheet of NFFP and PowerRips in a 1-step compression molding process for a high specific stiffness.

Amplitex natural fiber composites are used in the new Volvo EX30 for dashboard and door trim, in the Cupra Born for the front seats, and in the Polestar 3 combined with other sustainable materials (PowerRibs and NFPP).

The mapping for potential applications in the interior of an Alfa Romeo Stelvio comprises deco parts with natural-fiber look for the trunk, door panels, pillars, deco bezels, and panels in the center console and back seat.

Advantages include weight savings, carbon reduction, sustainability and circularity.

Session 2: Interior

Forvia: a Sustainable Mobility Tech Leader

Jean Baptiste Trollé, Forvia Asia Industrial Director

Forvia’s sustainability roadmap is centered on the idea use less, better and longer.

An example of the implementation of this roadmap is the monomaterial and modular seat. The seat is made of only 3 materials: metal for the structure, PET for the soft trim, and PP for hard plastics. The design approach is a thin, visibly modular and exposed frame. The same modular approach can be applied to interiors, where areconfigurability for instrument panels, door panels, and the center console has been introduced, to make sure the same structure can be used for more than one platform.

The biggest materials-related challenge designers are encountering is the need to accept the nonstandard colors of the recycled raw material, with limited possibilities to change them to an acceptable final color.

Materi’act, the Forvia brand created to massively develop and manufacture cutting-edge sustainable materials, will collaborate with Plastic Odyssey, an organization collecting plastic from the ocean and recycling it into consumer products. The cooperation, supported by the Forvia foundation, aims at transforming the plastic collected in the ocean into highly technical automotive parts.

The Path Towards Sustainability

Nicola dale Carbonare, Mario Levi Group Program Manager

Since 1946, the Mario Levi Group has been a leading tanning company in leather interiors. A renowned outstanding supplier for the automotive industry, today the Group also successfully operates in the railway, aviation, and bus sectors.

The company has presented a wide range of sustainable leather alternatives, which allow to get away from today’s highly polluting material processes, in favor of a green alternative helping to reduce emissions and supporting a circular economy.

Zeolite Leather

Zeolite tanning represents a solid alternative to both chrome & GDA tanning (a synthetic tanning agent) with two important benefits: it generates cleaner waste waterwithout additional treatment, and it improves the biodegradabilityof intermediate material.

Zeolites are microporous crystalline materials mainly consist of silicon, aluminum and oxygen; the three most abundant elements in Earth’s crust.

Avo Leather

From the meat industry and the olive oil production chain, a metal-free and GDA-free tanning technology that uses olive oil wastewaters as tanning agentfor leather.

Eco-Tan Leather

Ecotan leather uses natural ingredients and synthetic ‘bio circular polymers’. The result is a leather tanning system they say is safe, green, clean and bio circular.

Feel Tek

Polyurethane impregnated textile support, finished and embossed with genuine leather finishing technology. Iz is produced in two versions, the FeelTEk Bio with PU with bio-sourced content, and FeelTek Rec, 100-per-cent Recycled PES fibers + PU with Polyols from agriculture sources.

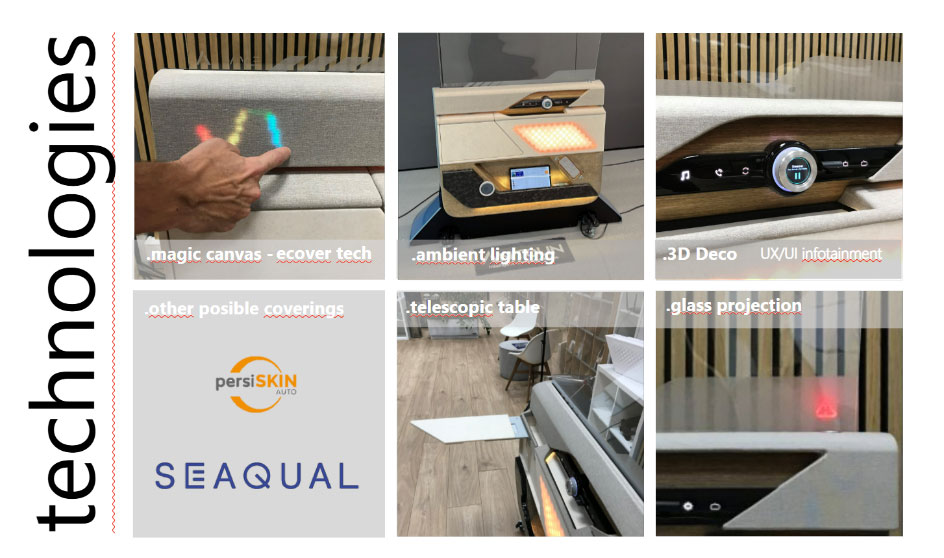

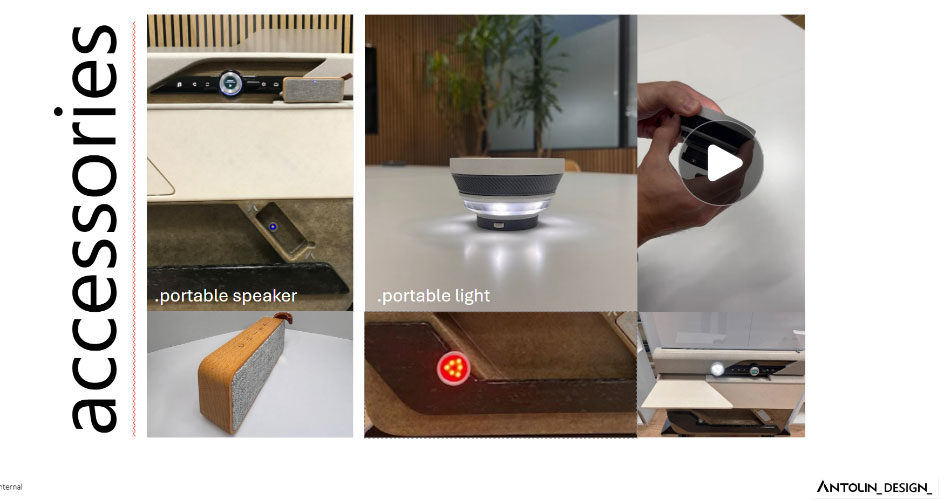

Antolin

VIV_e Door Panel: Crafting the Future of Eco-Conscious Comfort and Design

Alvaro Sanz Lazaro, Antolin Senior UX & CMF Designer

Antolin has introduced a new door panel concept, which includes sustainable materials and valuable functionality. Features included in the prototype door are:

- Thermal comfort in armrests

- Inductive charge in generated area

- Integrated telescopic table

- Smart deco peripheral with customizable illumination & touch area.

- Bolster in natural/recycled structure with light guide and proximity sensor

- Speaker area and detachable spotlight

- Window regulator, ambient lighting and interactive Surfaces.

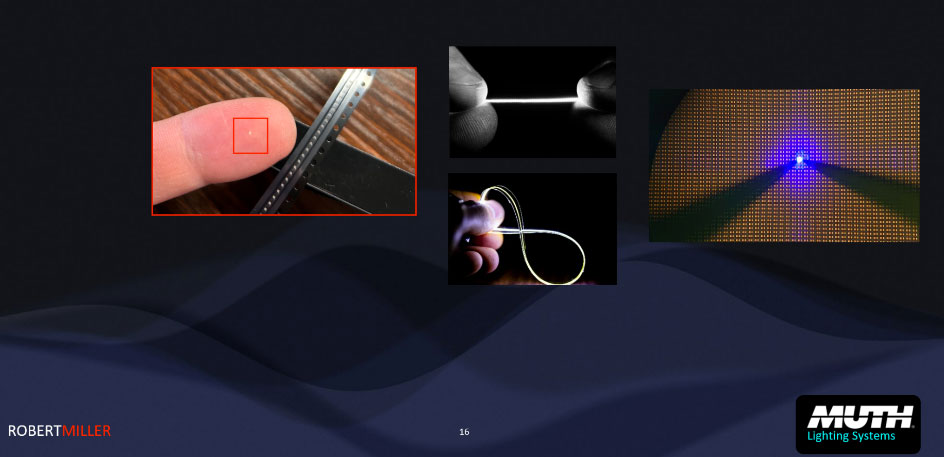

Muth Lighting

Interior lighting, focusing on energy-efficient solutions and materials that minimize environmental impact

Robert Miller, Executive Director and Board Member

Robert Miller described the possibilities to enhance interior lighting features combining microLeds and OLED in new materials.

Mini- and microLEDs are revolutionizing automotive interiors with compact, energy-efficient lighting. Their small size allows seamless integration into tight spaces, offering brighter, customizable lighting while consuming less power. This technology promotes sustainability through reduced materials use, improved durability, and lower energy use, enhancing functionality and aesthetics in modern vehicles.

MicroLEDs can be laminated to different transparent materials like glass and PC, offering designers new interior styling opportunities.

MicroLEDs offer high energy efficiency, superior brightness with long lifetimes, and low heat generation. They are compact and weigh little, allowing designers to integrate them seamlessly in tight spaces. And microLEDs can be incorporated into eco-substrates to reduce the environmental footprint.

Muth Lighting Systems is also developing OLED applications including flexible OLEDs and POLEDs for interior and exterior lighting.

Flexible OLEDs allow curved, seamless lighting designs that conform to various surfaces. This flexibility allows for thinner, more elegant displays and ambient lighting, enhancing aesthetics while offering energy-efficient, customizable lighting solutions.

Combining microLEDs and OLEDs with films and new material processes creates new lighting systems that can be recycled—even reused if needed.

A full range of possibilities in interior lighting design is emerging, and Muth offers a 360° service to its customers to achieve the best results respecting the environment.

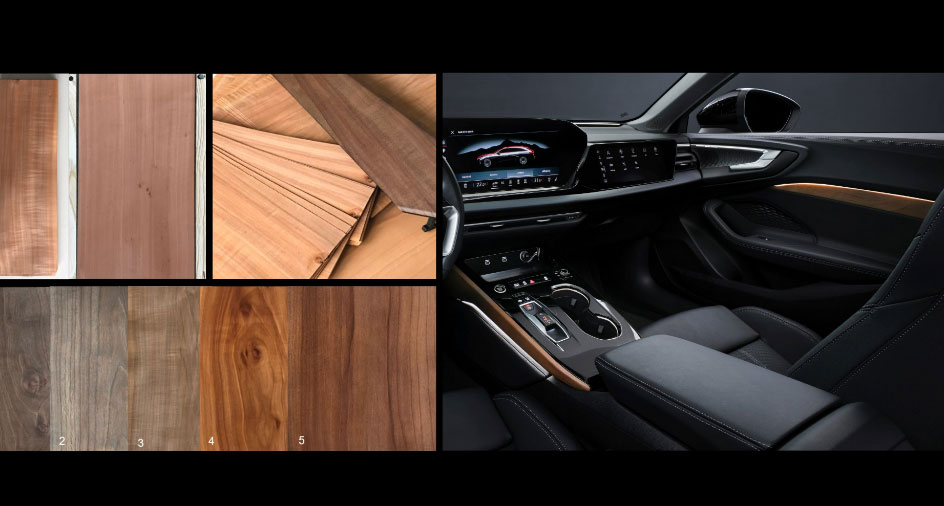

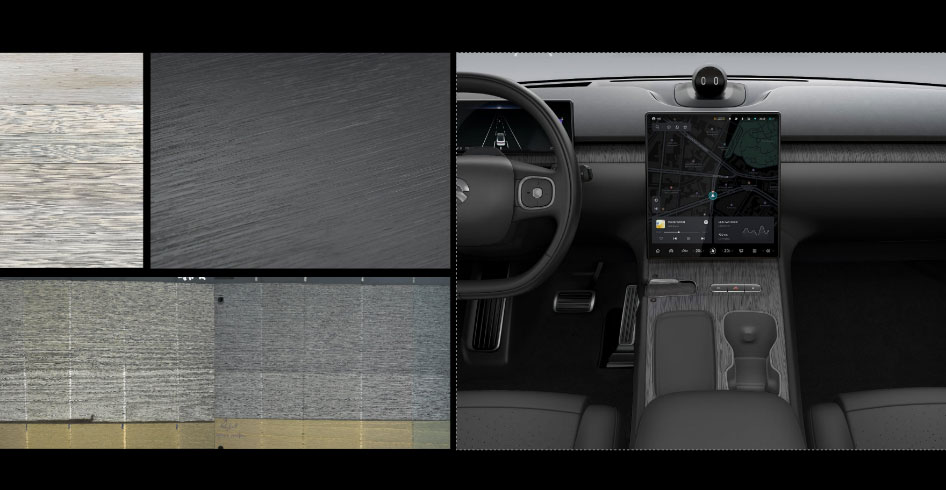

NBHX

Sustainable materials in automotive interior decoration

Thorsten Süss, Global Design Director

Thorsten Süss from NBHX introduced a full range of wood based sustainable surfaces for interior decoration.

Upcycled wood out of fruit trees! The wood comes from Europe; it is no longer fruitful and is therefore already felled. NBHX uses it to create beautiful surfaces.

Birch tree wood for veneers: this technically joined veneer comes from Europe and has been optimized to use a higher proportion of raw wood than was previously possible for automotive veneer production, creating less waste.

Karuun Nature Tech is an energy-efficient material. Its production process transforms the natural structure of the rattan palm into a unique composite material that is sustainable and appealing.

Jeans Textile Waste is re-shredded textile waste and powder out of the regrinding process, which can be used to dye materials.

All these new surface materials can be combined in wonderful palettes, which can offer, in addition to an optimized carbon footprint, also a ‘natural look’, reminding us of the sustainable origin of the materials.

Thin Film Technology as sustainable supporter for Circular Economy

Thorsten Klaski, Kurz Key Automotive Account Manager

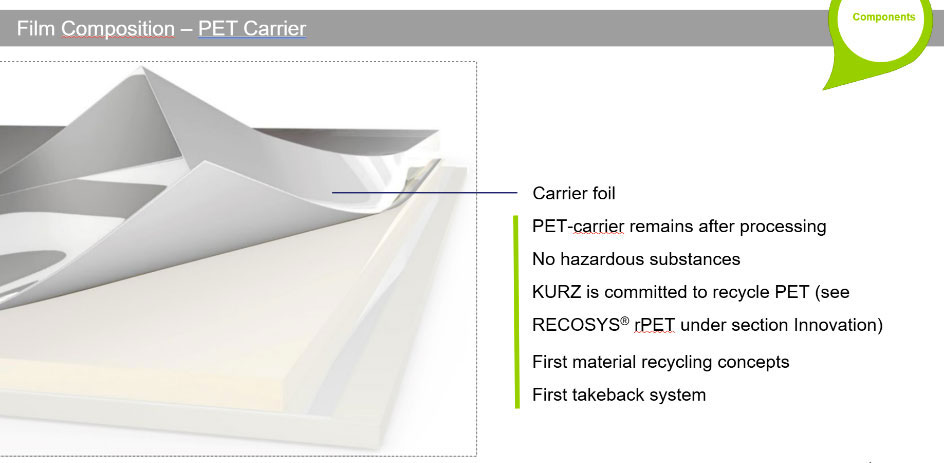

Kurz has been working on thin film technology, to support the achievement of the carbon footprint targets of the company and introduce a sustainable solution for a fundamental technology used today for many interior components and decorative parts.

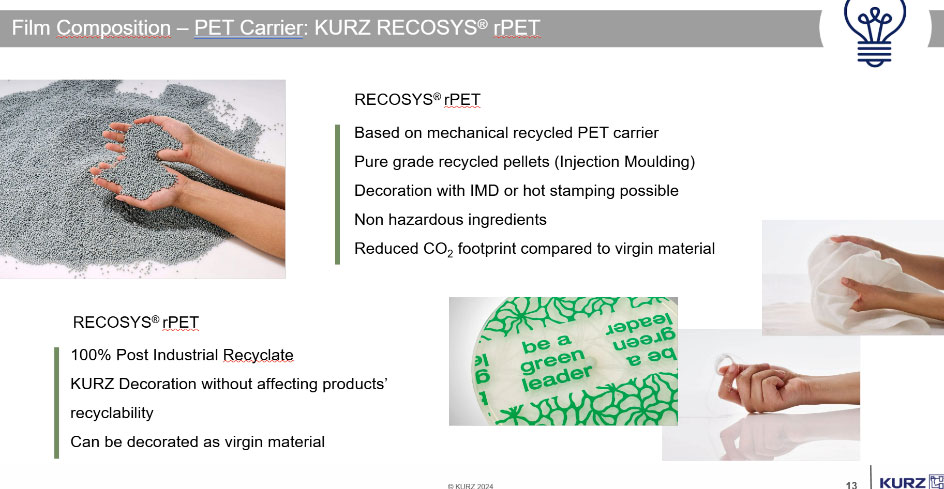

Kurz has redesigned the thin film introducing green solutions for both the carrier and the lacquer, introducing the first take back systems for PET carrier.

The PET-carrier of the film remains after processing, there are no hazardous substances used during the process, and it can be reused, by means of mechanical recycling, under the trade name Recosys rPET. This recycled PET is made of pure-grade recycled pellets, decoration with IMD or hot stamping is possible, and it has a reduced CO2 footprint compared to virgin material.

In addition, in lacquers formulations there is growing content of waterborne raw material and bio-based solvents, REACH conformity, and in accordance with RoHS.

The company powers their plants with photovoltaic systems and systems to recover energy during the process, like incineration of exhausted air to gain energy, and usage of elemental chromium for the printing process.

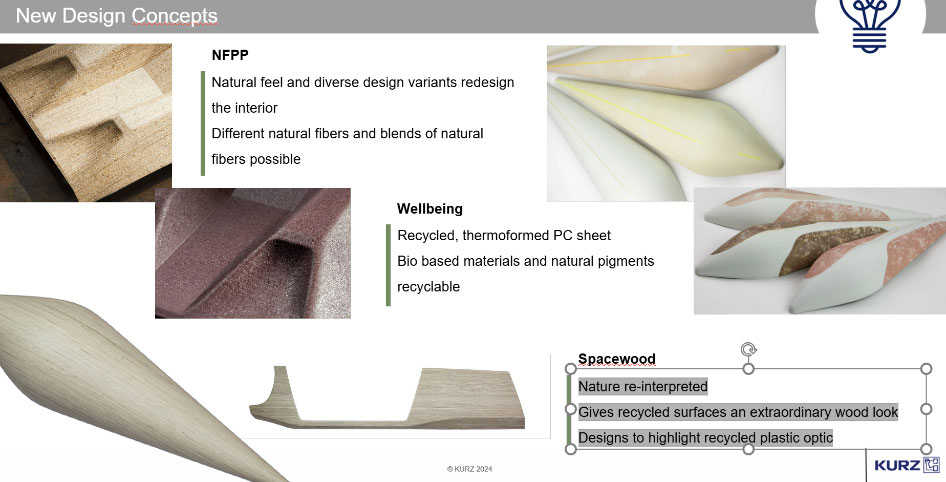

In addition, Kurz is developing new natural and sustainable surfaces, with the use of natural fibers and blends of natural fibers. These include:

- NFPP: natural feel and look with natural fibers

- Well Being: Recycled, thermoformed PC sheet with bio-based materials and natural pigments

- Spacewood: Gives recycled surfaces an extraordinary wood look. Designed to highlight recycled plastic optics.

Imaging photometry – one key factor to seamless lighting design

Tobias Porsch, TechnoteamApplication Engineer

Technoteam illustrated different methodologies to measure functional and ambient lighting, with the possibility to apply global and local uniformity features.

Tobias Porsch highlighted the differences in global and local uniformity analysis. Large amplitude of luminance differences (max. and min.) over the entire area to be measured (global effect) leads to superimposition of smaller (local) effects.

The global uniformity does not supply with information about the transition areas, and this can lead to a misinterpretation of the uniformity of this object related to visual perception.

The additional local uniformity analysis returns on the contrary with significant values about the homogeneity of the transition area. The kind of local feature extraction mimics visual perception.

In summary, a new method to define in a more precise way both ambient and functional lighting, which can be extensively used from the interior lighting industry.

Tactotek

Sustainable Automotive Interiors: Advancing Design with IMSE technology

Dominique Heilborn, Director Automotive

Several OEMs mentioned during presentations and open discussions the need to integrate more functionality in interior parts, to streamline the supply chain and reduce the number of components.

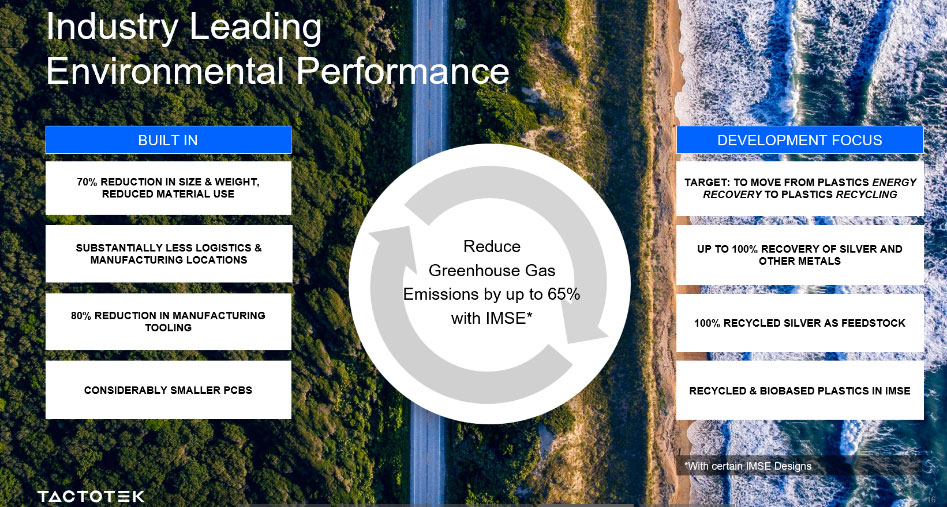

All advantages that Tactotek IMSE technology can offer, together with the possibility to influence in a considerable way the reduction of interior parts carbon footprint.

Tactotek is not a manufacturing company but a technology one, which licenses their IMSEto suppliers and automakers, and for years they have been building a strong ecosystem with injection moulding and material suppliers to support the introduction of IMSE in serial production.